Float switches play a crucial role in liquid level control across various industrial and residential applications. From preventing pump damage to maintaining optimal fluid levels, these simple yet effective devices have become indispensable in modern systems.

This comprehensive guide delves into the fundamentals of float switches, exploring their working principles, applications, installation methods, and different types available in the market.

Whether you’re a maintenance professional, system designer, or DIY enthusiast, understanding float switches is essential for implementing reliable liquid level control solutions.

How does a Float Switch Work?

The inner workings of float switches are elegantly simple yet highly effective. At their core, these devices use buoyancy to monitor liquid levels and control various systems. As the liquid rises or falls, a buoyant float moves along with it, triggering a switch mechanism at predetermined thresholds.

Inside the float switch, you’ll find a clever magnetic setup. The float contains a small magnet that interacts with a reed switch inside the stem or housing. When the float reaches a specific level, the magnet’s position changes, causing the reed switch to open or close the circuit. This simple action is the key to level control in countless applications.

You’ll often encounter two main types of float switches: Normally Open (NO) and Normally Closed (NC). NO switches activate devices when the liquid rises, while NC switches keep systems running until the liquid reaches a certain point.

Whether you’re dealing with water tanks, sump pumps, or industrial processes, float switches offer a reliable and cost-effective solution for liquid level management. Their versatility and straightforward operation make them a go-to choice for many level control needs.

What is a Float Switch used for?

Designed to monitor and control liquid levels, float switches serve an essential role in various applications across industries. You’ll find these clever devices in everything from domestic sump pumps to complex industrial systems.

Float switches are particularly vital in wastewater management, where they help maintain safe operation levels and prevent unwanted build-ups in drainage systems.

So, what exactly is a float switch for? Well, it’s a sensor for detecting when a liquid reaches a certain level. As the liquid rises or falls, the float switch will open or close, triggering a specific action. This could mean starting or stopping a pump, sounding an alarm, or activating a valve. It’s like having a vigilant guardian for your tanks and containers.

Float switches are particularly useful in preventing overflow situations. They’ll help you avoid those “oops” moments when a tank might otherwise spill over.

In wastewater management, they’re vital for maintaining safe operation levels. And in industrial settings, they’re instrumental in preserving product quality and efficiency. By integrating these nifty devices into your systems, you’re not just controlling liquid levels – you’re also boosting safety, reducing risks, and saving yourself from potential headaches down the line.

How do you wire a Float Switch?

Now that we understand the purpose of float switches, let’s address the practical aspect of wiring them. As a level sensor, your float switch can be wired in two main configurations: Normally Open (NO) or Normally Closed (NC). The NO configuration keeps the circuit open until the liquid level activates the switch, while NC remains closed until activated.

To wire your float switch correctly, you’ll need to consult the product manual for specific instructions and diagrams. It’s essential to install the switch at the right height in your tank to match your desired liquid level thresholds.

When wiring, use appropriate gauge wire that can handle the electrical load of connected devices. Don’t forget to insulate all connections properly to prevent short circuits or electrical failures.

Once you’ve completed the wiring, it’s time for a test run. Ensure your float switch activates and deactivates connected devices at the expected liquid levels. If needed, adjust the installation for optimal performance.

What do Normally Open and Normally Closed mean on a Float Switch?

Understanding the terms “normally open” and “normally closed” is essential when working with float switches. These configurations determine how your float switch will behave when detecting liquid levels.

A Normally Open (NO) float switch operates like this:

- It is in an open circuit state when the liquid level is low.

- As the liquid rises, the switch closes the circuit.

- This closure activates connected devices, such as pumps or alarms.

On the other hand, a Normally Closed (NC) float switch works differently. It remains in a closed circuit state when the liquid level is low, allowing current to flow continuously. When the liquid rises to the activation point, the switch opens the circuit, interrupting the current flow.

Choosing between NO and NC float switches depends on your specific application. If you need a device to turn on when the liquid reaches a certain level, you would opt for an NO switch. Conversely, if you want to deactivate a system when the liquid rises, an NC switch is your go-to.

What are the Types of Float Switches?

Float switches come in various types, each tailored to specific applications and environments. You’ll find that float switches are used in a wide range of industries, from residential to industrial settings.

The two main categories you’ll encounter are stem-mounted and cable-suspended float switches, each offering unique benefits for different installation needs.

When it comes to the type of float switch, you’ve got a few options to choose from. Mechanical float switches are a popular choice, especially in sump pumps and sewage systems. They use a simple float connected to a switch mechanism that responds to changes in liquid level.

If you’re dealing with hazardous environments, you might want to take into account magnetic float switches. These clever devices use a magnet and reed switch system, making them safer to use where direct electrical connections are a no-go.

For those of you looking for more precise control, electronic float switches are the way to go. They use sensors to detect liquid levels and can easily integrate with digital control systems, giving you that extra level of automation you might need.

-

%22%20transform%3D%22translate(.6%20.6)%20scale(1.17188)%22%20fill-opacity%3D%22.5%22%3E%3Cellipse%20fill%3D%22%23888%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(9.767%20-197.3651%2033.56754%201.66115%20110.2%2086)%22%2F%3E%3Cellipse%20fill%3D%22%23fff%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(-48.31403%20192.20864%20-72.43376%20-18.20712%20236.4%20113.3)%22%2F%3E%3Cellipse%20fill%3D%22%23fff%22%20cx%3D%2227%22%20cy%3D%22127%22%20rx%3D%2235%22%20ry%3D%22255%22%2F%3E%3Cellipse%20fill%3D%22%23949494%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(37.29267%20-29.78502%2018.45305%2023.10435%20123%2050.7)%22%2F%3E%3C%2Fg%3E%3C%2Fsvg%3E) Mouse Vertical Float Switch£28.80 +VAT

Mouse Vertical Float Switch£28.80 +VAT -

%27%20fill-opacity%3D%27.5%27%3E%3Cellipse%20fill%3D%22%23787878%22%20fill-opacity%3D%22.5%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22rotate(19.7%20-596.5%20435)%20scale(47.53784%2053.77584)%22%2F%3E%3Cellipse%20fill%3D%22%23fff%22%20fill-opacity%3D%22.5%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(61.08436%2022.15785%20-101.90043%20280.91734%20263.7%20204.8)%22%2F%3E%3Cellipse%20fill%3D%22%23fff%22%20fill-opacity%3D%22.5%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(-66.21608%20291.39952%20-76.85109%20-17.46323%20.6%20102.2)%22%2F%3E%3Cellipse%20fill%3D%22%23838383%22%20fill-opacity%3D%22.5%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(12.2574%2028.05847%20-28.32804%2012.37517%20111.5%20227.3)%22%2F%3E%3C%2Fg%3E%3C%2Fsvg%3E) KOSHIN Ponstar PBX / PBX7 MAC3 Float£36.00 +VAT

KOSHIN Ponstar PBX / PBX7 MAC3 Float£36.00 +VAT -

%22%20transform%3D%22translate(.6%20.6)%20scale(1.17188)%22%20fill-opacity%3D%22.5%22%3E%3Cellipse%20fill%3D%22%23354967%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22rotate(-173.9%2053.4%2027)%20scale(33.1465%20203.78223)%22%2F%3E%3Cellipse%20fill%3D%22%23fff%22%20cx%3D%22255%22%20cy%3D%22169%22%20rx%3D%22128%22%20ry%3D%22128%22%2F%3E%3Cellipse%20fill%3D%22%23496c9b%22%20cx%3D%22140%22%20cy%3D%2221%22%20rx%3D%2256%22%20ry%3D%2238%22%2F%3E%3Cellipse%20fill%3D%22%23fff%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22rotate(-177.8%207.5%2087.5)%20scale(33.88081%20255.00004)%22%2F%3E%3C%2Fg%3E%3C%2Fsvg%3E) Agma 22 Float Switch c/w 10m Cable£36.00 +VAT

Agma 22 Float Switch c/w 10m Cable£36.00 +VAT -

%27%20fill-opacity%3D%27.5%27%3E%3Cpath%20fill%3D%22%239e9f9b%22%20fill-opacity%3D%22.5%22%20d%3D%22M49.8%20140l193.4-51.5L97.9%20318.2z%22%2F%3E%3Cellipse%20fill%3D%22%23fff%22%20fill-opacity%3D%22.5%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(-85.31073%20286.39191%20-68.48176%20-20.39942%20275.6%20159.8)%22%2F%3E%3Cellipse%20fill%3D%22%23fff%22%20fill-opacity%3D%22.5%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(127.1561%2015.16245%20-5.9101%2049.56355%20218.7%2028.5)%22%2F%3E%3Cpath%20fill%3D%22%23838285%22%20fill-opacity%3D%22.5%22%20d%3D%22M137.1%20175.4l1.2%2064.4-49.3.9-1-64.5z%22%2F%3E%3C%2Fg%3E%3C%2Fsvg%3E) MAC3 Float Switch£28.80 +VAT

MAC3 Float Switch£28.80 +VAT -

%22%20transform%3D%22translate(.6%20.6)%20scale(1.17188)%22%20fill-opacity%3D%22.5%22%3E%3Cellipse%20fill%3D%22%23c7c7c7%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(-9.67565%20-48.54286%2033.59549%20-6.69631%20123%2014.8)%22%2F%3E%3Cellipse%20fill%3D%22%23c6c6c6%22%20cx%3D%22119%22%20cy%3D%22249%22%20rx%3D%2224%22%20ry%3D%2238%22%2F%3E%3Cpath%20fill%3D%22%23c9c9c9%22%20d%3D%22M109%2096h34v20h-34z%22%2F%3E%3Cellipse%20fill%3D%22%23fff%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(76.15315%2010.33319%20-20.84862%20153.64945%20211.3%20119)%22%2F%3E%3C%2Fg%3E%3C%2Fsvg%3E) JS ST-70AB Basic float switch£18.72 +VAT

JS ST-70AB Basic float switch£18.72 +VAT -

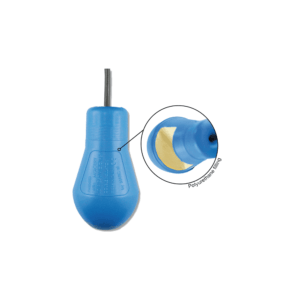

%27%20fill-opacity%3D%27.5%27%3E%3Cellipse%20fill%3D%22%23b45374%22%20fill-opacity%3D%22.5%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22rotate(116.5%2027.2%20121)%20scale(120.61219%2048.28724)%22%2F%3E%3Cellipse%20fill%3D%22%23fff%22%20fill-opacity%3D%22.5%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22rotate(22.6%20-203.5%20809.8)%20scale(73.89444%20298.82811)%22%2F%3E%3Cpath%20fill%3D%22%23fff%22%20fill-opacity%3D%22.5%22%20d%3D%22M-18.2-5.3L3%20318.2%20137.7-6.4z%22%2F%3E%3Cellipse%20fill%3D%22%239b4965%22%20fill-opacity%3D%22.5%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(19.71533%20-18.17155%2012.48915%2013.55017%20171.3%20107.7)%22%2F%3E%3C%2Fg%3E%3C%2Fsvg%3E) REKA 2000 Capacity Sensor Pump Float Switch£11.52 – £75.60Price range: £11.52 through £75.60 +VAT

REKA 2000 Capacity Sensor Pump Float Switch£11.52 – £75.60Price range: £11.52 through £75.60 +VAT -

%22%20transform%3D%22translate(.6%20.6)%20scale(1.17188)%22%20fill-opacity%3D%22.5%22%3E%3Cellipse%20fill%3D%22%23393939%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(-.81152%2068.59878%20-38.91196%20-.46033%20125%20143.5)%22%2F%3E%3Cellipse%20fill%3D%22%23949494%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(48.04294%201.50626%20-2.39019%2076.23622%20123.7%20146.3)%22%2F%3E%3Cellipse%20fill%3D%22%23fff%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22rotate(175.4%20108.3%2052)%20scale(69.58004%20247.74678)%22%2F%3E%3Cellipse%20fill%3D%22%23fff%22%20cx%3D%228%22%20cy%3D%2294%22%20rx%3D%2294%22%20ry%3D%2294%22%2F%3E%3C%2Fg%3E%3C%2Fsvg%3E) Matic ECO LM Sewage Float Built In Internal Counter Weight£42.48 – £54.72Price range: £42.48 through £54.72 +VAT

Matic ECO LM Sewage Float Built In Internal Counter Weight£42.48 – £54.72Price range: £42.48 through £54.72 +VAT -

%27%20fill-opacity%3D%27.5%27%3E%3Cellipse%20fill%3D%22%2378a7c2%22%20fill-opacity%3D%22.5%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(-63.18345%2045.1255%20-31.7493%20-44.45448%20132.5%20161.7)%22%2F%3E%3Cellipse%20fill%3D%22%2372c5fd%22%20fill-opacity%3D%22.5%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(-31.63368%202.60076%20-4.36468%20-53.08862%20103.5%20164)%22%2F%3E%3Cellipse%20fill%3D%22%23d8ccc1%22%20fill-opacity%3D%22.5%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(-53.5319%20-25.76317%2020.42083%20-42.43135%20181.4%20136)%22%2F%3E%3Cellipse%20fill%3D%22%23fff%22%20fill-opacity%3D%22.5%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(-156.26508%2087.3336%20-36.65388%20-65.5844%20239.6%20224.2)%22%2F%3E%3C%2Fg%3E%3C%2Fsvg%3E) Matic Little MC Sewage Float Switches£43.92 – £64.08Price range: £43.92 through £64.08 +VAT

Matic Little MC Sewage Float Switches£43.92 – £64.08Price range: £43.92 through £64.08 +VAT -

%27%20fill-opacity%3D%27.5%27%3E%3Cellipse%20fill%3D%22%230b6bb9%22%20fill-opacity%3D%22.5%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22rotate(-90.6%20137.4%2051.6)%20scale(115.27723%2049.08254)%22%2F%3E%3Cellipse%20fill%3D%22%23fff%22%20fill-opacity%3D%22.5%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(-19.6365%2064.75363%20-285.96842%20-86.71974%20157.5%2019.4)%22%2F%3E%3Cellipse%20fill%3D%22%23fff%22%20fill-opacity%3D%22.5%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(-123.99288%2065.36704%20-29.1021%20-55.20294%20253.2%20261.2)%22%2F%3E%3Cellipse%20fill%3D%22%2391a4ae%22%20fill-opacity%3D%22.5%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(-73.33602%2011.35302%20-6.44295%20-41.6189%20193.8%20159)%22%2F%3E%3C%2Fg%3E%3C%2Fsvg%3E) MATIC Multi Contact MC Sewage Floats£56.16 – £164.23Price range: £56.16 through £164.23 +VAT

MATIC Multi Contact MC Sewage Floats£56.16 – £164.23Price range: £56.16 through £164.23 +VAT

What are the best practices for Float Switches?

Implementing best practices for float switches is vital to guaranteeing their longevity and peak performance. When it comes to managing the level of liquid in a tank, you’ll want to keep your float switch in top shape. Regular inspections and maintenance are essential for reliable operation, helping you catch potential issues before they lead to costly failures.

To keep your float switch working like a charm, follow these three important tips:

- Clean your float switch periodically based on its environment to guarantee unobstructed movement.

- Select the right type and material for your specific liquid and conditions to maximise functionality.

- Train your team on proper installation and use to reduce errors and boost system reliability.

Don’t forget to document your maintenance activities – it’ll be a lifesaver when troubleshooting or optimising performance down the road.

Frequently Asked Questions

How Do Float Switches Work?

You’ll find that float switches work by using buoyancy. As liquid levels change, a float rises or falls, triggering a magnetic switch. This action closes or opens an electrical circuit, controlling devices like pumps or alarms.

What Is the Disadvantage of a Float Switch?

You’ll find that float switches have several drawbacks. They’re prone to mechanical failure, require regular maintenance, and can be tricky to install. They also offer limited sensing capabilities and may not work well with certain types of liquids.

Why do float switches fail?

Common causes of float switch failure include:

- Sediment buildup or debris preventing proper movement

- Mechanical wear of internal components

- Corrosion of electrical contacts

- Physical damage from impact or excessive force

- Water infiltration into the switch housing

- Faulty wiring connections

- Switch becoming stuck in one position

- Chemical damage from harsh substances

- Age-related deterioration of materials

- Improper installation causing restricted movement

Regular maintenance and inspection can help prevent many of these issues and extend the life of float switches.

Conclusion

You’ve now got a solid grasp on float switches. From understanding their working principles to wiring techniques and best practices, you’re equipped to handle these essential devices. At AES Rewinds are on hand to offer advice and support to help you find the right Float Switch for your application. Get in touch with us today to find out more.